BrickFix, from Safeguard Europe, is a simple, quick and cost-effective way to stabilise and repair cracked masonry. And now there’s an equally simple way to learn how to use it – a video which takes viewers through a graphic step-by step installation instructions, in around two-and-a-half minutes.

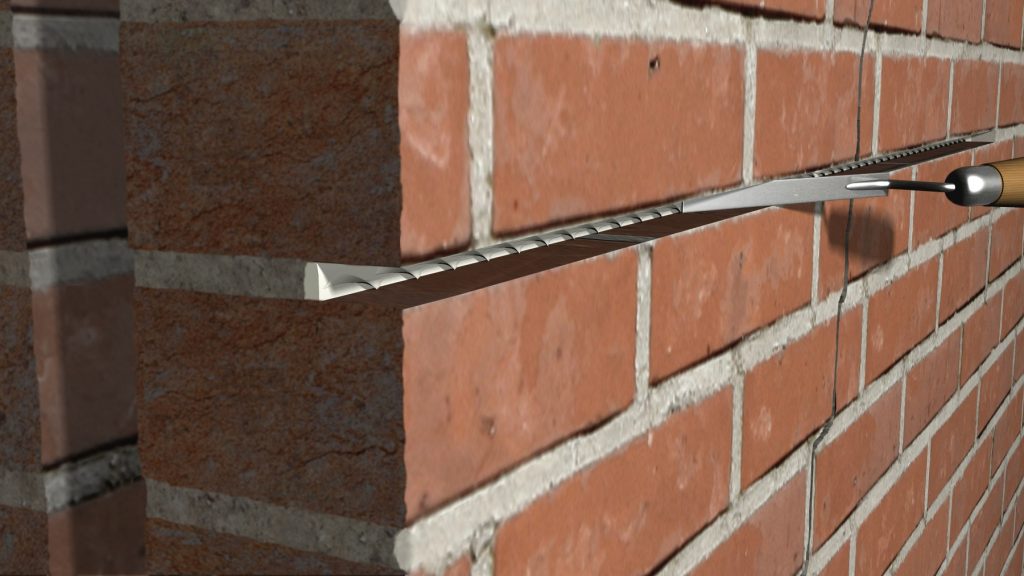

The BrickFix System consists of a series of helical austenitic steel bars which are grouted into chased-out mortar beds perpendicular to the line of a crack. Once in place, the repair minimises the likelihood of further cracking with the bar absorbing any localised stress.

Along with the steel bars, the BrickFix kits come with a two-part grout, mixing paddle, pointing gun and finger trowel. The helical bars are easily bent which means they can be used to stabilise cracks at the corners of a building or shaped to cope with the irregular masonry of older buildings.

The first step in the BrickFix process is to chase out a mortar bed, using a standard tool such as an angle grinder. The video demonstrates how the chased-out slot should be properly cleaned, using a pump to blow the dust out followed by washing with water. Once the mortar bed has been cleaned out, the grout is mixed and squirted into the slot in a continuous bead using the gun. There’s a proper way to mix the thixotropic grout – liquid first and then the powder – which the film short also highlights.

Next the bar is pressed into the grout, which quickly begins to set once in place, and a further layer of grout is applied and compressed with the finger trowel. Final steps see repointing of the mortar bed, and grouting the crack itself.

The bars come in 1m, 3m and 10m lengths and should be installed to extend at least 500mm either side of the crack. Several may be needed over the height of a crack usually placed every four to six brick courses or 300 to 450mm. The depth of slot ground in the mortar bed depends on the wall thickness.

It should be noted that BrickFix can’t cure the underlying causes of cracking, for example if a building is still moving due to subsidence. So it may be necessary to consult a structural engineer before any repair work is done.

“It’s important to us that the people using our products know how to get the best out of them, so that they can give their customers a high-quality, long-lasting job,” said Safeguard Europe director Hudson Lambert. “Animations are great because in a matter of seconds we can explain some small – but important – details, which can make all the difference to the quality of the repair.”

View the two-and-a-half minute BrickFix Crack Stitching tutorial at www.brickfix.co.uk or, along with other videos, on Safeguard Europe’s YouTube channel. More technical information is available on the website (www.safeguardeurope.com) or by calling Safeguard’s experts.